Newsletter

Sign up for industry alert, latest news products and events.

One of the core competencies of Navitas ASG’s cell R&D team is the development of high power cells. Several team members were key contributors to the development of A123 Systems’ AHR18700M1 Formula 1 racing cell, as well as to the development of later generations of the cell. This expertise served the ASG site well during later cell development projects, and two notable high power cells were developed for U.S. Government applications.

A large format mid-to-high power prismatic cell is currently in development at Navitas ASG. This cell features metal oxide chemistry, and is engineered for a balance of mid-to-high power along with moderate energy density (3800 W/kg, 150 Wh/kg). It is presently optimized for high power operation in low-temperature environments (10C at -18°C, 4C at -40°C)—a difficult operating regime for lithium-ion chemistry cells and a main driver of the cell’s overall high power design.

In addition to specifically high power cells, Navitas ASG has developed a variety of custom lithium-ion cells. More than ten custom lithium-ion cells have been designed and prototyped. Due to the high packaging and high packing efficiencies of prismatic cells, Navitas ASG has concentrated on prismatic cell design of both pouch-type cells and cells packaged in custom metal cans. The capacities of our cell portfolio range between 22mAh (a small, extremely thin metal can cell) and 45Ah (a large size metal can cell) with most cells in the 2 to 12Ah range. Cell chemistries have ranged from standard or custom nanophosphate to advanced custom metal oxide chemistries featuring extremely high energy density (600 Wh/L).

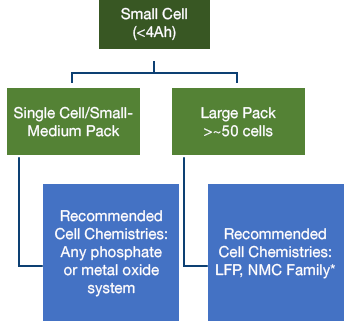

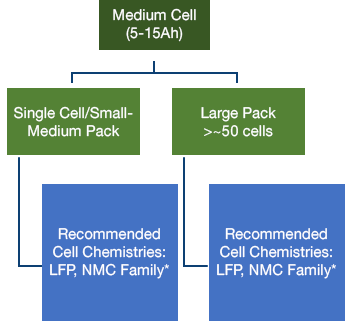

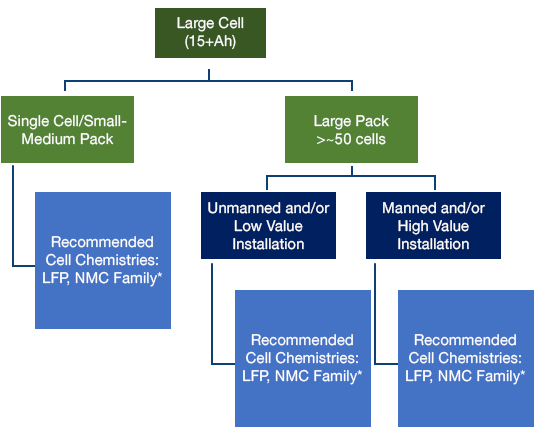

Navitas scientists and engineers are “Chemistry-Agnostic”, with deep experience in optimizing the right chemistry to the application.

*Higher energy density systems possible; perhaps derated for safety.

Sign up for industry alert, latest news products and events.

Sign up for industry alert, latest news products and events.